Metal laser cutting

Entrust your custom metal cutting to Usinage Laurentides. Take advantage of our personalized service to obtain metal parts exactly according to your specifications. With our expertise and state-of-the-art equipment, we guarantee high quality results to meet your specific needs. Our CNC laser cutting service is offered with state-of-the-art equipment. It is used in many fields to precisely cut different materials. It uses a focused laser beam to make clean, precise cuts on surfaces, whether it's metal, aluminum, stainless steel, plastic or more. Our company offers this service across Quebec.

Laser cutting for complex parts

Your manufacturing partner for excellence in laser cutting

Modern equipment combining speed and precision

Our latest generation equipment combines precision and speed to produce consistent high quality results:

Engineering, design and product development

We support manufacturers and agencies specializing in industrial design in prototyping, sourcing and manufacturing innovative products to solve today's challenges.

- Product research and development (R&D)

- Partner agencies in industrial design

- Prototyping and small series

- Optimization of technical drawings (3D and 2D)

Manufacturing of parts, complex products and mechanically welded assemblies

Benefit from the efficiency of work methods developed by solving the industrial challenges of our customers for more than 30 years.

- Medium/large series

- Finished metal products

- Parts intended for assembly

- Complex/unconventional parts

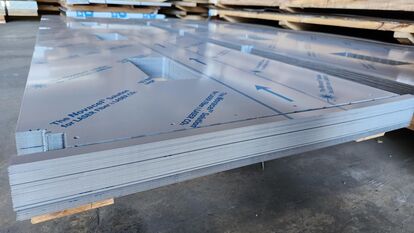

Sheet metal processing

Turnkey solutions for your steel and aluminum sheet processing needs.

- Steel, prepainted, stucco, aluminum & stainless steel

- Complex mechanically welded assemblies

- Numerically controlled cutting (CNC)

- Punching and punch/laser combo

- High precision machining

- Bending metal sheets

- Finishing and surface treatment

- Robotic, spot and manual welding

Critical point visual inspection and rigorous quality control

From the review of technical drawings to the inspection of parts between our departments, we ensure compliance with established criteria to ensure the delivery of finished products and durable metal parts.

- Validation of technical drawings before production

- Visual inspection of parts at critical points

- Updating a register of irregularities

- Production of non-conformity reports (NCR)

Continuous supply of production materials

Driven by innovation and continuous improvement, we have given ourselves the mission of constantly reinventing ourselves; so as to become the sole partner of choice for manufacturers of value-added products from here and elsewhere.

- Continuous supply

- Inventory management

- International import and export

- Supply chain optimization

- Just-In-Time Approach

Frequently asked questions about CNC laser cutting

Why subcontract laser cutting to Usinage Laurentides?

- Benefit from our know-how in laser cutting of complex metal parts.

- Modern equipment for precision cutting, even in medium or large series.

- Turnkey service, from design to final assembly.

- 360 transformation approach for innovation, plan improvement and cost reduction.

What cutters do you use to cut metal?

To ensure precise and efficient laser cutting, we use state-of-the-art equipment.

- Amada LCG 3015 AJ

- Finn-Power C6 punching machine

- Coastone Cone C15

What materials do you cut?

At Usinage Laurentides, we have the expertise to cut a variety of materials including steel. We are able to work with different types of materials, giving you flexibility in your projects.

- Prepainted steel

- Textured stucco steel

- Stainless steel

- Galvanized steel

- Aluminum

How to find the right supplier to cut sheet metal?

- Get ahead : Don’t wait until you have an urgent need to find a supplier

- Prepare yourself : Have drawings, forecasts, evaluation form on hand

- Communicate transparently : Share your issues and expectations.

- Exchange frequently and keep in touch : The situation of one or other of the parties may have changed, production capacities may no longer be the same, your volumes may have changed.

- Evaluate costs : Compare overall costs to unit costs

- Be precise : Specify potential volumes and supply rate

- Protect yourself : Complete a confidentiality agreement and sign a manufacturing agreement

What metal products can you cut?

- Complex parts intended for assembly.

- Unconventional metal parts.

- Finished metal products according to specific needs.

What is CNC laser cutting?

Laser cutting is a metal processing process that uses a laser beam to precisely and efficiently cut metal parts. This process allows for complex, high-quality cuts without the use of physical tools. Laser cutting offers high precision, low material distortion and exceptional surface finish.

What are the advantages of CNC laser cutting?

- Combination of laser cutting with a 33 ton punching machine for greater versatility.

- Turret storage system for maximum efficiency.

- Production line equipped with an automatic system for 24/7 use.

What is the production capacity of Usinage Laurentides? (dec)

Usinage Laurentides has two factories totaling 40,000 square feet. This allows us to guarantee continuous production, day and night, meeting your needs for tight deadlines and large quantities.

What are the laser cutting methods?

We use the punch + fiber laser combo method to guarantee precise and efficient cutting of your metal parts. This combination of techniques allows us to deliver high quality results, regardless of the complexity of your projects.

What is the average defect rate in laser cutting?

Our average defect rate in laser cutting is less than 1%. We are fast and committed to quality and we use an integrated production system to minimize errors and defects.

Do you have historical data on failure rates?

Yes, we have historical data on failure rates during laser cutting. Thanks to our integrated production system, our machines are connected to our ERP and we follow a rigorous quality manual. Additionally, each product is inspected according to customer specifications, ensuring consistent quality.

How do you ensure product quality during CNC laser cutting?

We implement several measures to ensure the quality of our products during CNC laser cutting.

- Validation of technical drawings before production.

- Visual inspection at critical points.

- Register of irregularities and non-compliance reports (RNC) if necessary.

- Continuous commitment to quality and process improvement.

How to choose a CNC cutting machine?

Selecting a CNC laser cutting machine can be a crucial decision for your business or project. Here are some important aspects to consider when selecting:

- Cutting needs

Determine the types of materials you plan to cut and their thickness. Certain materials require specific lasers, so it is important to select a machine compatible with your cutting needs. - Accuracy and speed

Precise cutting is essential to achieve high-quality results, while high cutting speed can increase your business productivity. - Laser power

The power of the laser is an important factor to consider. The higher the power, the more the machine will be able to cut thick and hard materials. However, higher power can also lead to higher costs.

What is the maintenance and upkeep of the CNC cutting machine?

Regular maintenance and servicing of CNC laser cutting equipment is essential to ensure its proper operation and extend its lifespan. Here are some tips to ensure effective maintenance:

- Regular cleaning

Clean CNC laser cutting equipment regularly to remove cutting residue, dust and debris. Use appropriate cleaning products and be sure to dry surfaces thoroughly after cleaning. - Checking the optics

Machine optics, including lenses and mirrors, should be checked and cleaned regularly. Make sure they are clean and well aligned to get precise cuts. - Lubrication

The moving parts of the machine must be properly lubricated to prevent excessive friction and ensure smooth movement. Use lubricants recommended by the manufacturer and follow the recommended lubrication intervals. - Calibration

Calibrating the machine is important to ensure that cuts are made accurately. Check the machine calibration regularly and adjust it if necessary. - Replacement of wearing parts

Wearing parts, such as belts, bearings and cutting heads, must be replaced regularly to avoid performance problems. Follow the manufacturer's recommendations for parts life and replacement.

What are the types of CNC cutting machines?

There are different types of CNC laser cutting machines available in the market. The main types include fiber and CO2. Each type of machine uses a different laser source to perform the cutting.

Fiber laser cutting machines are commonly used to cut metals. They use a fiber optic laser to focus the laser beam, resulting in precise and fast cuts in metals such as stainless steel, aluminum, sheet metal.

CO2 laser cutting machines are ideal for cutting non-metallic materials such as wood and plastic. They use a CO2 laser which is absorbed by these materials, causing them to heat and evaporate to make precise cuts.

Sectors

Laser cutting adapted to your industry

Electrical sector

From prototyping to mass production, we manufacture metal parts for products in the electrical industry and clean technologies.

- Electric charging stations

- Industrial transformers

- Battery components

- Electric vehicles

Transport and heavy vehicles

We manufacture parts for vehicle components of all categories including the bodywork, interior, access components, fasteners and more.

- Electric vehicles and mobility vehicles

- Heavy vehicles & collection vehicles

- Emergency and leisure vehicles

Signage

Manufacturing of finished products and complex metal parts intended for assembly for the sign and signaling sector.

- Road sign

- Commercial display

- Traffic lights

- Control systems

Entertainment and fun

Manufacturing of finished products and complex metal parts intended for assembly for products in the entertainment and amusement sector.

- Scenes

- Chassis and mechanized benches

- Racing and flight simulators

- Arcades and amusement parks

HVAC

Manufacture of finished products and complex metal parts intended for assembly for the HVAC sector.

- Components of ventilation systems

- Heating system components

- Components of air conditioning systems

Handling and Storage

Manufacturing of finished products and complex metal parts intended for assembly for products in the handling and warehousing sector.

- Racking and roll out racks

- Palletizing and lifting systems

- Specialized Warehousing Systems

- Industrial trolleys and tool boxes

Furnishing

Manufacturing of finished products and complex metal parts intended for assembly for products in the furniture sector.

- Displays

- Fixtures

- Commercial furniture

- Specialized furniture

- Modular systems

- Lighting systems

Health and medical

Manufacturing of complex metal parts intended for the assembly of medical products and devices for the health sector.

- Hospital equipment (beds, wheelchairs, stretchers)

- Medical devices

- Laboratory furniture

- Mobility Equipment

Experts en transformation

Other metal transformation processes

CNC machine tool

CNC bending

Usinage Laurentides puts at your disposal its latest generation bending machines and its 30 years of experience in metal bending and bending. Obtain high quality finished products or metal parts for assembly that require complex bending processes.

Robotic, spot and manual welding

Attentive to your needs, we adjust to your realities. We offer you models for manufacturing and production in short, medium and large series thanks to the commitment of our teams and our passion for excellence, constantly motivated by innovation.

- 6-axis robotic welding

- Manual welding

- Spot welding

Assembly of metal parts

Engineering makes sure to understand the requirements of your original drawings, the factory produces for you while you take care of other tasks.

- Mechanically welded assembly

- Riveting

- Bonding

- Bolting

Finish and surface treatment

Whether the finishing is done at our factories or at our partners, you are assured that we will have the quality of everything that comes back to you. Our integrated service offering accelerates processing time while ensuring quality control from A to Z.

- Grinding and sandblasting

- Surface preparation

- Powder coating and electroplating (E-coat)

- Plating and epoxy primer