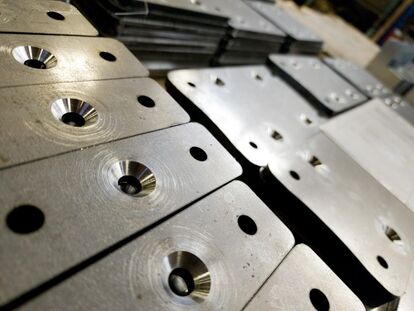

Custom parts | Complex

Mass production

Benefit from the efficiency of work methods developed by solving the industrial challenges of our customers for more than 30 years.

- Medium/large series

- Finished metal products

- Parts intended for assembly

- Complex/unconventional parts

Turnkey metal parts manufacturing service

Parts prototyping

Before going into mass production, a prototype of the part is usually created. This allows the design to be tested and validated, potential problems to be identified and adjustments to be made if necessary. Some machine shops offer this service.

Supply

At Usinage Laurentides, we are committed to providing you with a reliable and efficient supply to meet your metal parts needs. With Usinage Laurentides, you benefit from a reliable supply, optimized inventory management and effective coordination with our partners.

Production

Our production department at Usinage Laurentides is supported by our two processing and manufacturing plants, which are specially designed to meet your needs efficiently and reliably. With a total of 30,000 square feet of production space , we have the capacity to meet the most demanding demands. Thanks to our state-of-the-art equipment and technical resources, we are able to maintain production capacities day and night. We have the capacity to meet your tight deadlines and your urgent needs. Whether you have short-term projects or large-scale productions, our team is ready to meet any challenge.

Optimization

Using our expertise and advanced technologies, we are able to analyze your current manufacturing process and identify areas that can be improved. Whether by automating certain tasks, optimizing production flows or using more efficient materials, we will offer you tailor-made solutions to optimize your operations.

Control the quality of the manufactured parts

Materials inspection

Before the start of manufacturing, the metallic materials (metal, stainless steel, etc.) used are checked to ensure that they comply with the required standards and specifications. This may include resistance testing, chemical analysis or other appropriate evaluation methods.

Process control

Throughout the manufacturing process, checks are carried out to ensure that the various stages are carried out correctly. This may involve dimensional checks, weld tests, precision measurements, etc.

Checking dimensions and tolerance

Custom metal parts must match the dimensions and tolerances specified by the customer. Precise measuring tools are used to check if the dimensions are correct and if the tolerances are respected.

Performance testing

Depending on the application of the part, performance tests can be performed to assess its strength, durability, functionality, etc. These tests may include mechanical strength tests, fatigue tests, pressure tests, etc.

Documentation and traceability

Rigorous monitoring of quality control processes is carried out by the machine shop, all stages and results are documented. This guarantees the traceability of the parts and provides precise information in case of later need.

Manufacture of complex metal parts

Your manufacturing partner of excellence in the manufacture of metal parts

Modern equipment combining speed and precision

Our latest generation equipment combines precision and speed to produce consistent high quality results:

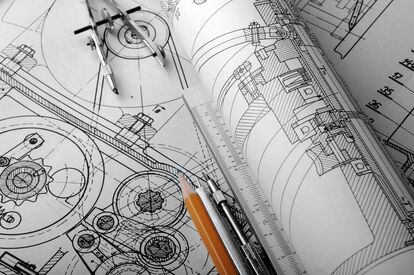

Engineering, design and product development

We support manufacturers and agencies specializing in industrial design in prototyping, sourcing and manufacturing innovative products to solve today's challenges.

- Product research and development (R&D)

- Partner agencies in industrial design

- Prototyping and small series

- Optimization of technical drawings (3D and 2D)

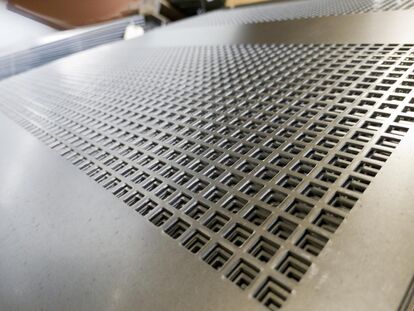

Sheet metal processing

Turnkey solutions for your steel and aluminum sheet processing needs.

- Steel, prepainted, stucco, aluminum & stainless steel

- Complex mechanically welded assemblies

- Numerically controlled cutting (CNC)

- Punching and punch/laser combo

- High precision machining

- Bending metal sheets

- Finishing and surface treatment

- Robotic, spot and manual welding

Visual inspection by critical points and rigorous quality control

From the review of technical drawings to the inspection of parts between our departments, we ensure compliance with established criteria to ensure the delivery of finished products and durable metal parts.

- Validation of technical drawings before production

- Visual inspection of parts at critical points

- Updating a register of irregularities

- Production of non-conformity reports (NCR)

Continuous supply of production materials

Driven by innovation and continuous improvement, we have given ourselves the mission of constantly reinventing ourselves; so as to become the sole partner of choice for manufacturers of value-added products from here and elsewhere.

- Continuous supply

- Inventory management

- International import and export

- Supply chain optimization

- Just-In-Time Approach

Electrical sector

From prototyping to mass production, we manufacture metal parts for products in the electrical industry and clean technologies.

- Electric charging stations

- Industrial transformers

- Battery components

- Electric vehicles

Transport and heavy vehicles

We manufacture parts for transport and heavy vehicle components of all categories including bodywork, interior, access components, fasteners and more.

- Heavy vehicles and collection vehicles

- Emergency and leisure vehicles

- Mobility vehicles and electric vehicles

Signage

Manufacture of finished products and complex metal parts intended for assembly for the sign and signaling sector.

- Road sign

- Commercial display

Entertainment and fun

Manufacture of finished products and complex metal parts intended for assembly for products in the entertainment and amusement sector.

HVAC

Manufacture of finished products and complex metal parts intended for assembly for the HVAC sector.

- Components of ventilation systems

- Heating system components

- Components of air conditioning systems

Furnishing

Manufacture of finished products and complex metal parts intended for assembly for products in the furniture sector.

- Displays

- Fixtures

- Commercial furniture

Health and medical

Manufacture of complex metal parts for the assembly of medical products and devices for the health sector.

Experts en transformation

Manufacturing processes for metal parts

CNC cutting

Entrust your custom metal cutting to Usinage Laurentides. Take advantage of our personalized service to obtain metal parts exactly according to your specifications. With our expertise and state-of-the-art equipment, we guarantee high quality results to meet your specific needs.

- Laser cut

- Digital cutting (CNC)

- Hallmark

- Stamping

CNC machine tool

CNC bending

Usinage Laurentides puts at your disposal its latest generation bending machines and its 30 years of experience in metal bending and bending. Obtain high quality finished products or metal parts for assembly that require complex bending processes.

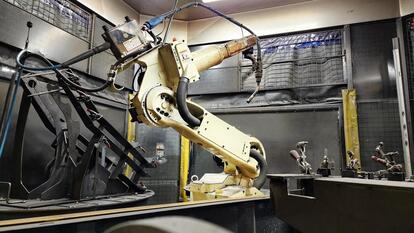

Robotic, spot and manual welding

Attentive to your needs, we adjust to your realities. We offer you models for custom manufacturing and production in short, medium and large series thanks to the commitment of our teams and our passion for excellence, constantly motivated by innovation.

- 6-axis robotic welding

- Manual welding

- Spot welding

Assembly of metal parts

Engineering makes sure to understand the requirements of your original drawings, the factory produces for you while you take care of other tasks.

- Mechanically welded assembly

- Riveting

- Bonding

- Bolting

Finish and surface treatment

Whether the finishing is done at our factories or at our partners, you are assured that we will have the quality of everything that comes back to you. Our integrated service offering accelerates processing time while ensuring quality control from A to Z.

- Grinding and sandblasting

- Surface preparation

- Powder coating and electroplating (E-coat)

- Plating and epoxy primer