Mechanical welding and mechanically welded structure

Welded assembly mechanically processes

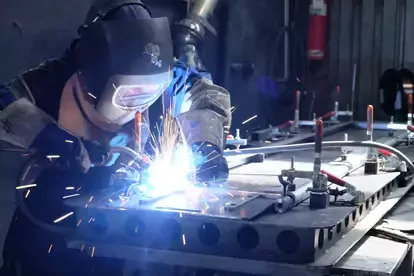

Embarking on the captivating journey of mechanically welded assembly processes unveils a realm where innovation meets precision. At the heart of this technological marvel is gas tungsten arc welding (TIG welding), a welding process, that intricately weaves together the artistry of welds and assembly with the science of a non-consumable tungsten electrode. Picture a dance of controlled heat and versatility across materials, a symphony of perfection.

Now, amplify this precision with the rhythmic cadence of robotic welding. The marriage of TIG welding and robotic prowess transcends industries, reshaping the landscape of manufacturing. From the sleek contours of automotive masterpieces to the structural grace of aerospace wonders, these processes signify not just welds but a seamless fusion of art and engineering. In the world of mechanically welded assemblies, each spark signifies a step forward into a future where precision and innovation are the guiding stars across diverse industrial horizons.

Manufacturing of parts, complex products and mechanically welded assemblies

Explore precision weld bead quality and expertise at Mechanical Welding by Usinage Laurentides. With our skilled welders and advanced robotic welding systems, we create strong weld bead area using TIG welding. Our commitment to excellence ensures quality under any pressure. At our workshop, we don't just clean welds; we shape industries with precision weld beads and expertise.

Weld assembly for industries with manufacturials needs

Automotive Industry

Welded assemblies are integral in the manufacturing of vehicles, encompassing components and assemblies such as frames, chassis, and exhaust systems assemblies. Precision welding ensures structural integrity and safety in automobiles.

Aerospace Sector

In the aerospace industry, where lightweight and durable materials are crucial, welded assemblies play a vital role in constructing aircraft frames, fuselage components, and engine structures.

Construction and Infrastructure

Welded metal assemblies are extensively used in the construction industry for fabricating structural metal components, bridges, and buildings. The strength and stability provided by welded metal assemblies and structures contribute to enhance the longevity of infrastructure projects.

Heavy Machinery Manufacturing

Industries involved in the production of heavy machinery, such as construction equipment and mining machinery, rely on welded assemblies for robust and durable structural components, ensuring the machinery's performance and safety.

Energy and Power Generation

Welded assemblies are crucial in the fabrication in the energy sector for constructing components like pipelines, pressure vessels, and support structures for power generation facilities. The precision of welded assemblies and joints is essential for maintaining the integrity of these critical systems.

The Advantages of Mechanical Welding

Mechanical and welding process, a process synonymous with precision weld quality and efficiency, brings a multitude of advantages to various industries. Here are key points highlighting the benefits of embracing mechanical and welding process.

Precision Engineering

Mechanical and welding process ensures unparalleled precision in the assembly process, allowing more options for the creation of intricate weld, and accurate welds that meet the highest industry standards.

Enhanced Structural Integrity

Welded joints produced through mechanical welding techniques result in weld joint and in structures and metals with superior strength and durability, contributing to enhanced overall structural integrity.

Versatility Across Industries

The adaptability of mechanical welding makes it suitable for a wide range of industries, from automotive manufacturing to aerospace and construction, where diverse materials and specifications are common in weld well.

Efficiency through Automation

The incorporation of automated processes, such as robotic welding, increases efficiency by streamlining production and reducing the likelihood of errors. This results in faster turnaround times and improved productivity.

Consistent Quality

Mechanical and welding process ensures consistent and reliable welds and quality, minimizing variations in the final product. This reliability is crucial for industries where product uniformity and repeatability is a prerequisite for safety and performance.

Cost-Effective Solutions

The efficiency and precision of mechanical welding contribute to cost-effective metals' solutions by minimizing material wastage, less corrosion, reducing the need for metal rework, and optimizing overall metal production processes.

Adherence to Strict Standards

Mechanical welding processes adhere to stringent industry standards, ensuring that the final products meet or exceed regulatory requirements. This is especially crucial in sectors where safety and compliance are paramount.

Mechanical welding by Usinage Laurentides

Your manufacturing partner of excellence

Modern equipment combining speed and precision

Our latest generation equipment combines precision and speed to produce consistent high quality results:

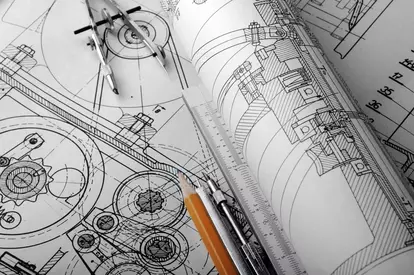

Engineering, design and product development

We support manufacturers and agencies specializing in industrial design in prototyping, sourcing and manufacturing innovative products to solve today's challenges.

- Product research and development (R&D)

- Partner agencies in industrial design

- Prototyping and small series

- Optimization of technical drawings (3D and 2D)

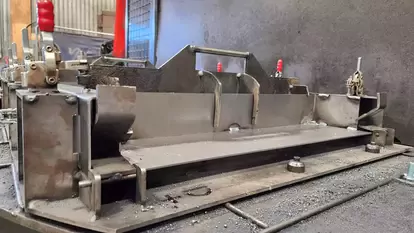

Manufacturing of parts, complex products and mechanically welded assemblies

Benefit from the efficiency of work methods developed by solving the industrial challenges of our customers for more than 30 years.

- Medium/large series

- Finished metal products

- Parts intended for assembly

- Complex/unconventional parts

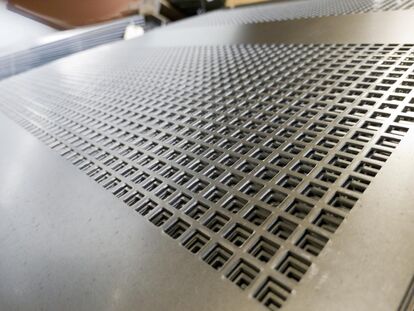

Sheet metal processing

Turnkey solutions for your steel and aluminum sheet processing needs.

- Steel, prepainted, stucco, aluminum & stainless steel

- Complex mechanically welded assemblies

- Numerically controlled cutting (CNC)

- Punching and punch/laser combo

- High precision machining

- Bending metal sheets

- Finishing and surface treatment

- Robotic, spot and manual welding

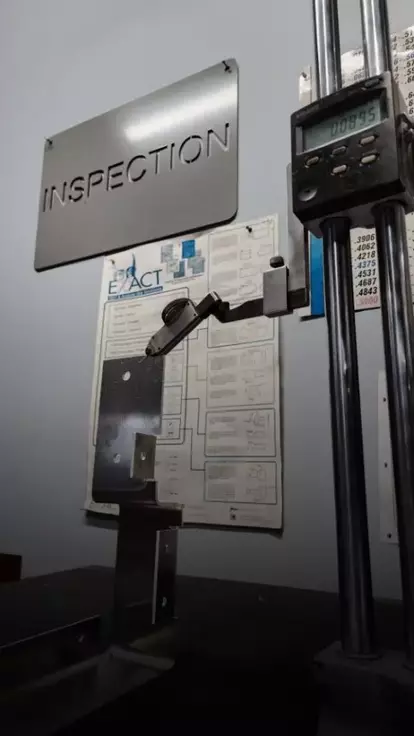

Inspection visuelle par point critique et contrôle qualité rigoureux

From the review of technical drawings to the inspection of parts between our departments, we ensure compliance with established criteria to ensure the delivery of finished products and durable metal parts.

- Validation of technical drawings before production

- Visual inspection of parts at critical points

- Updating a register of irregularities

- Production of non-conformity reports (NCR)

Continuous supply of production materials

Driven by innovation and continuous improvement, we have given ourselves the mission of constantly reinventing ourselves; so as to become the sole partner of choice for manufacturers of value-added products from here and elsewhere.

- Continuous supply

- Inventory management

- International import and export

- Supply chain optimization

- Just-In-Time Approach

Frequently asked questions about mechanically welded assembly

Why subcontract the mechanically welded assembly to Usinage Laurentides?

- Benefit from our know-how in assembling complex metal parts.

- Modern machinery for precision assemblies, even in medium or large series.

- Turnkey service, from design to final assembly.

- 360 transformation approach for innovation, plan improvement and cost reduction.

What equipment do you use to join metal?

We use cutting-edge machinery to meet your mechanical welding assembly needs.

- The 7-axis welding robot OTC FD Series and Techno Control

- Spot welding

What materials do you assemble?

We have the expertise to assemble a variety of materials including steel. We are able to work with different types of materials, giving you flexibility in your projects.

- Prepainted steel

- Textured stucco steel

- Stainless steel

- Galvanized steel

- Aluminum

How to find the right supplier to assemble mechanically welded products?

- Get ahead : Don’t wait until you have an urgent need to find a supplier

- Prepare yourself : Have drawings, forecasts, evaluation form on hand

- Communicate transparently : Share your issues and expectations.

- Exchange frequently and keep in touch : The situation of one or other of the parties may have changed, production capacities may no longer be the same, your volumes may have changed.

- Evaluate costs : Compare overall costs to unit costs

- Be precise : Specify potential volumes and supply rate

- Protect yourself : Complete a confidentiality agreement and sign a manufacturing agreement

What mechanically welded products can you assemble?

- Complex parts intended for assembly.

- Unconventional metal parts.

- Finished metal products according to specific needs.

What is welded assembly?

Welded assembly is a manufacturing process that involves assembling metal parts using both welding and mechanical welding techniques. This makes it possible to create strong and durable metal structures that are very popular in the industrial sector.

What are the advantages of mechanically welded assembly?

- Consistent quality thanks to a reproducible manufacturing process.

- Accurate and reliable results thanks to process repeatability.

- High productivity guaranteeing a large number of parts within tight deadlines.

- Reduction of rejects by minimizing the risks of failure or non-compliance of assemblies.

What is the production capacity of Usinage Laurentides?

Usinage Laurentides has two factories totaling 40,000 square feet. This allows us to guarantee continuous production, day and night, meeting your needs for tight deadlines and large quantities.

What are the assembly methods for mechanically welded products?

We use different joining methods including TIG welding, MIG welding and MAG welding. These techniques allow us to assemble different types of metal materials with precision and reliability.

What is the average defect rate in the welded assembly?

Our average defect rate in the welded assembly is less than 1%. We are fast and committed to quality and we use an integrated production system to minimize errors and defects.

Do you have historical data on failure rates?

Yes, we have historical data on our failure rates during welded assembly. Thanks to our integrated production system and connected machines, we are able to track and analyze this data. We also use an ERP system and a quality manual to ensure the traceability and conformity of each product. Additionally, each product is inspected according to customer specifications to ensure quality.

How do you ensure product quality during welded assembly?

We implement several measures to ensure the quality of our products during mechanically welded assembly.

- Validation of technical drawings before production.

- Visual inspection at critical points.

- Register of irregularities and non-compliance reports (RNC) if necessary.

- Continuous commitment to quality and process improvement.

Electrical sector

From prototyping to mass production, we manufacture metal parts for products in the electrical industry and clean technologies.

- Electric charging stations

- Industrial transformers

- Battery components

- Electric vehicles

Transport and heavy vehicles

We manufacture parts for transport and heavy vehicle components of all categories including bodywork, interior, access components, fasteners and more.

- Heavy vehicles

- Emergency and leisure vehicles

- Collection vehicles

- Mobility vehicles

- Electric vehicles

Signage

Manufacture of finished products and complex metal parts intended for assembly for the sign and signaling sector.

- Road sign

- Commercial display

Entertainment and fun

Manufacture of finished products and complex metal parts intended for assembly for products in the entertainment and amusement sector.

HVAC

Manufacture of finished products and complex metal parts intended for assembly for the HVAC sector.

- Components of ventilation systems

- Heating system components

- Components of air conditioning systems

Furnishing

Manufacture of finished products and complex metal parts intended for assembly for products in the furniture sector.

- Displays

- Fixtures

- Commercial furniture

Manutention et Entreposage

Manufacturing of finished products and complex metal parts intended for assembly for products in the handling and warehousing sector.

- Racking

- Palletizing systems

- Roll out Racks

Health and medical

Manufacture of complex metal parts for the assembly of medical products and devices for the health sector.

Experts in mechanically welded structure

Other metal transformation processes

CNC cutting

Entrust your metal cutting to Usinage Laurentides. Take advantage of our personalized service to obtain metal parts exactly according to your specifications. With our expertise and state-of-the-art equipment, we guarantee high quality results to meet your specific needs.

- Laser cut

- Digital cutting (CNC)

- Hallmark

- Stamping

CNC machine tool

CNC bending

Usinage Laurentides puts at your disposal its latest generation bending machines and its 30 years of experience in metal bending and bending. Obtain high quality finished products or metal parts for assembly that require complex bending processes.

Robotic, spot and manual welding

Attentive to your needs, we adjust to your realities. We offer you models for manufacturing and production in short, medium and large series thanks to the commitment of our teams and our passion for excellence, constantly motivated by innovation.

- 6-axis robotic welding

- Manual welding

- Spot welding

Assembly of metal parts

Engineering makes sure to understand the requirements of your original drawings, the factory produces for you while you take care of other tasks.

- Mechanically welded assembly

- Riveting

- Bonding

- Bolting

Finish and surface treatment

Whether the finishing is done at our factories or at our partners, you are assured that we will have the quality of everything that comes back to you. Our integrated service offering accelerates processing time while ensuring quality control from A to Z.

- Grinding and sandblasting

- Surface preparation

- Powder coating and electroplating (E-coat)

- Plating and epoxy primer